Cambridge ALD

Jump to navigation

Jump to search

| |

| Essentials | |

|---|---|

| Full name | Savannah S100 (gen. 1) |

| Manufacturer | Cambridge NanoTech (Veeco) |

| Description | Atomic layer deposition system |

| Location | Cleanroom 1 (03.2.209A) Cleanroom 2 (03.2.203B) |

| Responsibility | |

| Primary | Harry |

| Secondary | Martin |

Page last updated: 11 Nov 2025 Two nearly identical Savannah S100-like systems are used for atomic layer deposition of aluminum, hafnium, titanium, zirconium, and oxide.

Other material deposition alternatives at the NBI cleanroom:

- AJA systems for sputtering/e-gun evaporation

- E-Gun evaporator

- Edwards thermal evaporator

- Leica sputter coater

- Molecular beam epitaxy system

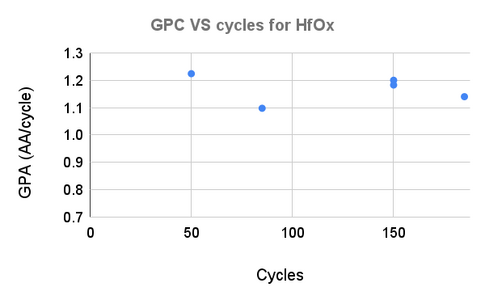

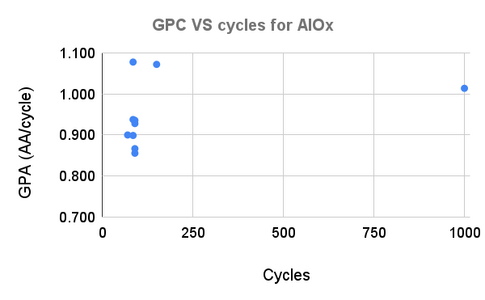

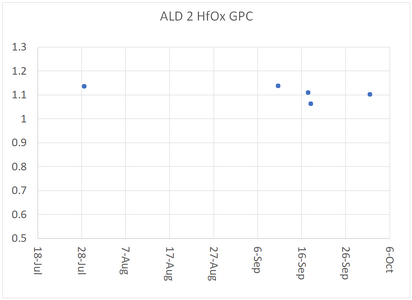

Growth per cycle (GPC) monitoring

-

ALD1 HfOx

-

ALD1 AlOx

-

ALD2 HfOx

Available processes

| Deposited material | Precursor | ALD1 | ALD2 | Ref. |

|---|---|---|---|---|

| Hafnium oxide (HfOx, HfO2) | Yes | Yes | [1] | |

| Aluminum oxide (AlOx, Al2O3) | Yes | Yes | [2] | |

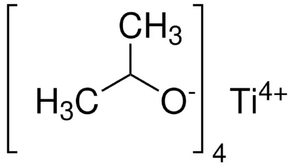

| Titanium oxide (TiOx, TiO2) | Yes | No | [3] | |

| Zirconium oxide (ZrOx, ZrO2) | No | Yes | [4] |

Videos on operating the tools

Video on how to operate ALD 1:

Video on how to operate ALD 2:

Standard operating procedure

- Log your process in the Excel notebook.

- Check the nitrogen bottle:

- Verify that the main valve on top of the bottle is open.

- The N2 flow in idle state is 5 sccm.

- Verify that the main bottle pressure is at least 5 bar.

- The line pressure should be >1 bar (ALD1) 1-2 bar (ALD2).

- If line pressure is outside the range, please report it to the cleanroom staff.

- Make sure the valves of all precursors inside the ALD machine are closed.

- Run recipe Default_cleaning to pump out any residual gas in the gas lines.

- Press the VENT or VENT REACTOR button.

- Open the metal lid.

- Put your sample inside, roughly in the center, away from the gas inlet and outlet.

- Check whether the rubber O-ring is properly seated.

- Close the metal lid. Check that the lid is aligned to sit directly on top of the reactor chamber.

- Press the PUMP or PUMP REACTOR button.

- Pressure with flow set to 0: ~5e-2 Torr or lower.

- Place the metal cage on top of the tool.

- Open relevant precursor valves.

- Run your recipe.

- Pressure with 20 sccm N2 flow present: low e-1 Torr.

- ALD1 pulse lengths: H2O ~0.5 s, HfOx TDMAH 0.2 s, AlOx TMA 0.02 s.

- ALD2 pulse lengths: H2O ~0.02 s, HfOx TDMAH 0.2-0.5 s.

- Close precursor valves.

- Press the big round VENT or VENT REACTOR button.

- Place the metal cage on the side of the tool.

- Take out your sample. Check the rubber o-ring.

- Press the big round PUMP or PUMP REACTOR button.

- Run recipe Default_heater_set.

- Verify that the flow is set at 5 sccm.

Witness samples

In CR1 and CR2, you can find various witness samples depending on the properties that you would like to explore:

- Only thickness: Si (001) of dimension > 7x7 mm2

- Thickness and breakdown voltage: Si (001) 15x15 mm2 back-side Au plated

It is recommended to ash the witness chips for 2 mins before loading them in the ALD tool.

File logs

- Recipe file location

- ALD1: C:\Savannah\Users\Standard\

- ALD2: C:\Cambridge Nanotech\Recipes\

- Log file location

- ALD1: C:\ALD data. Includes pressure data, screenshot at termination.

- ALD2: C:\Cambridge Nanotech\Log\. Includes pressure and heater temperature data, screenshot at termination, software event logs.

Troubleshooting

- Pressure reading obviously wrong (above 1e3 Torr or below 1e-4 Torr)

- Pressure gauge failure. Unplug the network cable from the small square pressure gauge beneath the chamber and plug it back in. The pressure reading should return to expected values.

- No peak visible during precursor pulse

-

- Precursor valves closed. Make sure the relevant precursor valves are open. Consult the labels on the inside of the door.

- Pulse time too short. Select the lowest plotting interval and check whether you can spot a small peak when the automatic valve opens. Increase pulse time as needed.

- Cannot open lid upon venting

-

- Chamber pressure still below atmosphere. Confirm pressure reading in software. If pressure is below 5e2 Torr, check whether the nitrogen bottle valve is open.

- Rubber O-ring can get stuck to the lid. Gently but firmly lift the lid. Reseat the O-ring if needed.

- What is the best plot time to graph the process pressure?

- It is recommended to plot only several pulses, for example 30 seconds or 1 minute total plot time. Setting this value to 1 hour during a run can reduce delay precision, because with a 1 hour plot time many data points need to be refreshed, which consumes a lot of processing resources. It is possible to set the plot time to 1 hour to get an overview of pulse heights, but plot times > 5 minutes are not recommended during a run. [1]

- What are the recommended heater temperatures?

- These are the recommended temperatures from the manual:

- Heaters for the trap (#6):150°C

- Stop valve (#7): 150°C

- ALD valve oven (#10): 150°C

- Precursor Manifold: 150°C

- Reactor heaters (#8 and #9): 100-200°C

- ALD1 (#8 and #9): 110°C

Remote access

- TeamViewer: ALD1, ALD2

- LogMeIn: ALD1 (CR1), ALD2 (CR2)

References

- ↑ Savannah Maintenance Manual