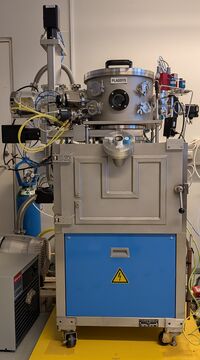

Plassys Evaporator

| |

| Essentials | |

|---|---|

| Full name | MEB550S |

| Manufacturer | Plassys |

| Description | Evaporation system |

| Location | 1st floor lab (03.2.213) |

| Responsibility | |

| Primary | Harry |

| Secondary | Martin |

Overview

Physical vapour deposition tool of aluminium via e-beam evaporation for Josephson junction fabrication.

It also provides an ion gun for surface preparation and etching purposes.

The system has the capability of in-situ oxidation.

The sample stage can be cooled with LN2.

Film Quality: Surface roughness - 1.6 nm for 100nm thick film ( scan area 2 um /AFM Analysis (June 2023)

Currently loaded materials

| Crucible position | Material | Comment |

|---|---|---|

| 1 | Ti | Currently In Use |

| 2 | - | Empty |

| 3 | - | Empty |

| 4 | Al | NBI crucible |

| 5 | Al | NQCP crucible |

Substrates allowed

- Silicon and Sapphire only

- III/V substrates are not allowed in the chamber

Standard Operating Procedure

This is the standard operating procedure for the Plassys evaporator at the process lab on the second floor.

Pre-checks and log in

Pre-checks

- Is the oxygen alarm beeping?

- Leave the room immediately and notify the cleanroom staff

- Log the loadlock and main chamber pressures in the Excel log sheet at the external computer.

- PLL ~ 1e-7 bar

- Pmain < 5e-8 bar

- Verify that the turbopump and the cryopump are both running (check main software interface)

- Turbo should be running on 100% speed

- Tcryo should be in the range 12-15 K

- Verify that nobody has loaded a sample and that no user is logged on

Log in

- Click on the

logged offindication of the GUI and use your group's credentials to log in

Sample loading

- On the

- LL state -side of the user interface clickVENT - Wait for the load lock to vent.

- The venting is complete when you stop hearing the hissing sound of the N2 line

- Wear gloves. Sleeves and hair net are also recommended.

- Use the stepping stool to have better access to the loadlock

- Be careful with the ventilation unit above the tool

- Open the loadlock lid

- Use the dedicated screwdriver to loosen the three main screws

- Rotate the holder to release it from the main stage.

- Place the holder on a cleanroom wipe on the table

- Close the LL lid

- Clamp your substrate to the holder. There are many available holders. Use the one that your group recommends.

- Keep the unused holders in the N2 desiccator

- Align the holder pin with the pin in the chamber. This will help you with any angled evaporations.

- Tighten the screws with the dedicated screwdriver and place it back in its holder.

- On the

- LL state -side of the user interface, clickPUMP- The loadock will start pumping first with the scroll pump (up to 1e-1 bar) and then with the turbopump.

Load your recipe

While the loadlock is pumping down, you can prepare your recipe

- Click on the Edit process icon

File > Open recipe> ...Choose from your group folde- Edit the main parameters such as time, thickness, and tilt

- Save the recipe

- On the saved recipe name you automatically get the date added

- Close the window

Excecute your recipe

- Are you doing evaporation?

- Turn on the Carrera power supply

- Are you doing milling?

- Turn on the Kaufman control unit and open the valve of the argon bottle

- Are you doing oxidation?

- Verify that the oxygen bottle valve is open

- Click on the Run process icon

- Load your recipe

- Verify all your steps

- Click

Execute

Monitor your process

- Do not leave the system unattended

- During your process, you will be asked multiple times to check that the system is in the correct state and you need to be present to aknowledge these messages

- Keep the viewport shutter always closed

- There is a polariser filter on the viewport that you can use when the crucible is bright. See the indications about the positioning of the polariser (transparent vs opaque)

Sample unloading

- Accept the Process complete pop-up message

- Turn off the Carrera power supply, Kaufman controller, and close the valces of the gas bottles

- On the

- LL state -side of the user interface clickVENT - Wait for the load lock to vent.

- The venting is complete when you stop hearing the hissing sound of the N2 line

- Wear gloves. Sleeves and hair net are also recommended.

- Use the stepping stool to have better access to the loadlock

- Be careful with the ventilation unit above the tool

- Open the loadlock lid

- Use the dedicated screwdriver to loosen the three main screws

- Rotate the holder to release it from the main stage.

- Place the holder on a cleanroom wipe on the table

- Close the LL lid

- Remove your chip from the holder.

- Wipe the holder with ethanol

- Place the holder back into the loadlock.

- If you used a holder from your own group, then place your holder back into the descicator and load the holder that was initially in the chamber.

- Align the holder pin with the pin in the chamber.

- Tighten the screws with the dedicated screwdriver and place it back in its holder.

- On the

- LL state -side of the user interface, clickPUMP- The loadock will start pumping first with the scroll pump (up to 1e-1 bar) and then with the turbopump.

- Verify that the load lock is pumping down

- Go to

Fileand Log off - Verify that the surfaces are tidy, there are no excess wipes on the table and you left no samples or sample boxes behind.