Etching: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

=Wet etching= | |||

https://transene.com/etch-compatibility/ | https://transene.com/etch-compatibility/ | ||

Data comparing different bottles of transene type D: Etching on Si, InAs (001), and GaAs(001) | Data comparing different bottles of transene type D: Etching on Si, InAs (001), and GaAs(001) | ||

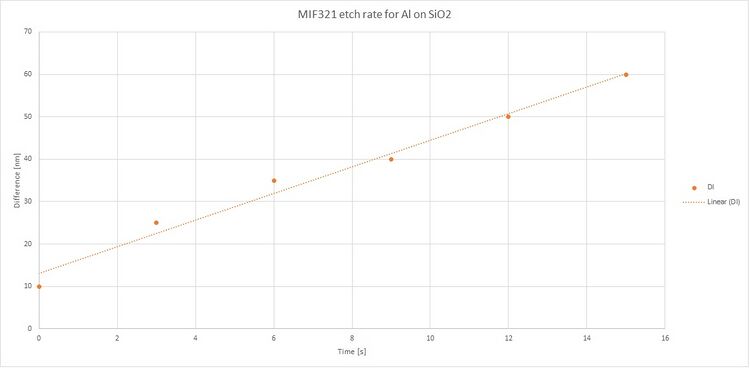

= Etch rate with MIF321 = | == Etch rate with MIF321 == | ||

The Al/SiO2 chips are developed in MIF321 for 50 sec, before etching. | The Al/SiO2 chips are developed in MIF321 for 50 sec, before etching. | ||

| Line 26: | Line 28: | ||

[[File:MIF_etch.jpg|750px]] | [[File:MIF_etch.jpg|750px]] | ||

=Dry etching= | |||

For dry etching, you can use [[AJA systems]] or [[Plassys Evaporator]]. AJA1 and Plassys have an Ion gun for DC milling, and in AJA2 you can do RF milling. | |||

==Erch rate with AJA2== | |||

Milling of SiOx on Si for 5 minutes at different pressures | |||

== 6 mTorr == | |||

{| class="wikitable" | |||

|- | |||

| Power [W] | |||

| 50 | |||

| 100 | |||

| 150 | |||

| 200 | |||

| 250 | |||

|- | |||

| Δh [nm] | |||

| 2.7 | |||

| 9.8 | |||

| 13.5 | |||

| 24.3 | |||

| 38.3 | |||

|} | |||

== 12 mTorr == | |||

{| class="wikitable" | |||

|- | |||

| Power [W] | |||

| 50 | |||

| 100 | |||

| 150 | |||

| 200 | |||

| 250 | |||

|- | |||

| Δh [nm] | |||

| 3.0 | |||

| 13.6 | |||

| 16.2 | |||

| 35.9 | |||

| 47.9 | |||

|} | |||

== 18 mTorr == | |||

{| class="wikitable" | |||

|- | |||

| Power [W] | |||

| 50 | |||

| 100 | |||

| 150 | |||

| 200 | |||

| 250 | |||

|- | |||

| Δh [nm] | |||

| 5.5 | |||

| 10.4 | |||

| 47.3 | |||

| 57.0 | |||

| 77.3 | |||

|} | |||

== 24 mTorr == | |||

{| class="wikitable" | |||

|- | |||

| Power [W] | |||

| 50 | |||

| 100 | |||

| 150 | |||

| 200 | |||

| 250 | |||

|- | |||

| Δh [nm] | |||

| 3.7 | |||

| 17.3 | |||

| 35.1 | |||

| 53.1 | |||

| 72.7 | |||

|} | |||

== 6 mTorr == | |||

{| class="wikitable" | |||

|- | |||

| Power [W] | |||

| 50 | |||

| 100 | |||

| 150 | |||

| 200 | |||

| 250 | |||

|- | |||

| Δh [nm] | |||

| 2.7 | |||

| 9.8 | |||

| 13.5 | |||

| 24.3 | |||

| 38.3 | |||

|} | |||

== 12 mTorr == | |||

{| class="wikitable" | |||

|- | |||

| Power [W] | |||

| 50 | |||

| 100 | |||

| 150 | |||

| 200 | |||

| 250 | |||

|- | |||

| Δh [nm] | |||

| 3.0 | |||

| 13.6 | |||

| 16.2 | |||

| 35.9 | |||

| 47.9 | |||

|} | |||

== 18 mTorr == | |||

{| class="wikitable" | |||

|- | |||

| Power [W] | |||

| 50 | |||

| 100 | |||

| 150 | |||

| 200 | |||

| 250 | |||

|- | |||

| Δh [nm] | |||

| 5.5 | |||

| 10.4 | |||

| 47.3 | |||

| 57.0 | |||

| 77.3 | |||

|} | |||

== 24 mTorr == | |||

{| class="wikitable" | |||

|- | |||

| Power [W] | |||

| 50 | |||

| 100 | |||

| 150 | |||

| 200 | |||

| 250 | |||

|- | |||

| Δh [nm] | |||

| 3.7 | |||

| 17.3 | |||

| 35.1 | |||

| 53.1 | |||

| 72.7 | |||

|} | |||

{| class="wikitable" | |||

|- | |||

! rowspan="2" |Power [W] !! colspan="4" |Δh [nm] | |||

|- | |||

! !! 6mTorr !! 12mTorr !! 18mTorr !! 24mTorr | |||

|- | |||

| 50 |2.7|3.0|5.5|3.7| | |||

|- | |||

| 100|9.8|13.6|10.4|17.3| | |||

|- | |||

| 150|13.5|16.2|47.3|35.1| | |||

|- | |||

| 200|24.3|35.9|57.0|53.1| | |||

|- | |||

| 250|28.3|47.9|77.3|72.7| | |||

|} | |||

Revision as of 12:05, 8 September 2025

Wet etching

https://transene.com/etch-compatibility/ Data comparing different bottles of transene type D: Etching on Si, InAs (001), and GaAs(001)

Etch rate with MIF321

The Al/SiO2 chips are developed in MIF321 for 50 sec, before etching.

| Time [seconds] | 0 | 3 | 6 | 9 | 12 | 15 |

| Δh [nm] | 10 | 25 | 35 | 40 | 50 | 60 |

Dry etching

For dry etching, you can use AJA systems or Plassys Evaporator. AJA1 and Plassys have an Ion gun for DC milling, and in AJA2 you can do RF milling.

Erch rate with AJA2

Milling of SiOx on Si for 5 minutes at different pressures

6 mTorr

| Power [W] | 50 | 100 | 150 | 200 | 250 |

| Δh [nm] | 2.7 | 9.8 | 13.5 | 24.3 | 38.3 |

12 mTorr

| Power [W] | 50 | 100 | 150 | 200 | 250 |

| Δh [nm] | 3.0 | 13.6 | 16.2 | 35.9 | 47.9 |

18 mTorr

| Power [W] | 50 | 100 | 150 | 200 | 250 |

| Δh [nm] | 5.5 | 10.4 | 47.3 | 57.0 | 77.3 |

24 mTorr

| Power [W] | 50 | 100 | 150 | 200 | 250 |

| Δh [nm] | 3.7 | 17.3 | 35.1 | 53.1 | 72.7 |

6 mTorr

| Power [W] | 50 | 100 | 150 | 200 | 250 |

| Δh [nm] | 2.7 | 9.8 | 13.5 | 24.3 | 38.3 |

12 mTorr

| Power [W] | 50 | 100 | 150 | 200 | 250 |

| Δh [nm] | 3.0 | 13.6 | 16.2 | 35.9 | 47.9 |

18 mTorr

| Power [W] | 50 | 100 | 150 | 200 | 250 |

| Δh [nm] | 5.5 | 10.4 | 47.3 | 57.0 | 77.3 |

24 mTorr

| Power [W] | 50 | 100 | 150 | 200 | 250 |

| Δh [nm] | 3.7 | 17.3 | 35.1 | 53.1 | 72.7 |

| Power [W] | Δh [nm] | |||

|---|---|---|---|---|

| 6mTorr | 12mTorr | 18mTorr | 24mTorr | |

| 2.7|3.0|5.5|3.7| | ||||

| 9.8|13.6|10.4|17.3| | ||||

| 13.5|16.2|47.3|35.1| | ||||

| 24.3|35.9|57.0|53.1| | ||||

| 28.3|47.9|77.3|72.7| | ||||