Loomis scriber: Difference between revisions

| Line 60: | Line 60: | ||

* Press <code>Tool up</code> | * Press <code>Tool up</code> | ||

* Press <code>Peck once</code> | * Press <code>Peck once</code> | ||

* Check the peck line: | * Check the peck line: | ||

** Is it aligned with the crosshair? | ** Is it aligned with the crosshair? | ||

Revision as of 11:56, 8 July 2025

| |

| Essentials | |

|---|---|

| Full name | Loomis LSD-155 |

| Manufacturer | Loomis Inc |

| Description | Automated semiconductor scriber and breaker |

| Location | 1st floor lab (03.1.111) |

| Responsibility | |

| Primary | Harry |

| Secondary | Martin |

Other tools at the NBI cleanroom for wafer processing:

About

The Loomis LSD-155 is a production scribe and break system that can be used for processing large grids, arrays of laser bars, cleaving high quality mirror facets, and dicing wafers.

Primarily, it is dedicated to scribe and dice III/V samples, but it is also possible to use it for Si.

You can read the news about the tool in the designated Teams channel of UCPH_NBI_Cleanroom called Loomis

Policy

Users and training

Only a limited number of users are trained on this tool. If you want to dice a wafer using this tool, contact cleanroom@nbi.ku.dk.]. Please include the following details:

- Amount, material and crystal orientation of wafers.

- Dicing dimensions

- Is your wafer patterned? A schematic is well appreciated

- Resist that the sample is coated

General

- Always dispose of the membrane after a single use. Never reuse a membrane.

Standard operating procedure

Load your sample to the membrane

How to load it

Initialise settings and calibrate

- Place the tape ring on the stage. Slide the ring underneath the two black tabs and ensure that it is sitting flush on the bottom bezel of the stage

- Rotate the retaining lever to secure the tape ring.

- Press

Load Wafer - Press

Load Recipeand select Si 001. - Choose the right tool

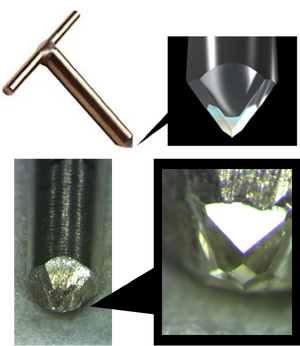

A scribe tool is a bar with a faceted diamond attached to its end. Every facet and feature of a Loomis scribe tool exists to create the optimum scribe line. The leading edge of the diamond point encourages ductile flow of material around the point as it travels across the wafer, much like the flow of water around the keel of a boat. The trailing edge is responsible for the stress crack that travels down into the wafer. The scribe lines break cleanly and leave edges on the resultant dice that have integrity and strength.

- Press

Change tool - Find an area that you are fine if it gets damaged and press

Tool down

- If Tool touch indicates >TOOL OFF< then:

- Rotate the wheel behind the microscope lens counterclockwise.

- While rotating the indication will change to >TOOL ON<. At that point, stop turning the wheel.

- Press

Tool up - Press

Peck once - Check the peck line:

- Is it aligned with the crosshair?

- Yes all good

- No adjust the croshair by pressing

Recticlein the correct x-direction (->or<-)so that it matches the peck line - Can't see the peck line at all? Bring the tool a bit more down by rotating the wheel of the previous steps further. Then, repeat pecking.

- Is it aligned with the crosshair?

- If you want to save the sample position that you are in right now, press right click on

XV2andXV1to store the positions.- Right click is storing, left click is going

Scribe single lines

- Press

Two Point Theta Adj- Follow the dialogue at the bottom right of the screen to align with a high-order crystal symmetry

- Check how well the alignment is by driving through the line.

- You can also do a quick alignment by right-clicking on two different points of the screen. However, the final alignment is recommended to be done with the

Two Point Theta Adj.

- You can also do a quick alignment by right-clicking on two different points of the screen. However, the final alignment is recommended to be done with the

- Find the point that you want to scribe and press

Scribe - If you want to navigate with specific coordinates go to

Recipe manager>Technicaland edit thex-index- You only move across X, so don't edit the Y-index. The Y-index will be used later for the BREAK command, and it was found to be 63.5mm

- Scribe all lines in the first direction

- Single right click on the rotation button to rotate (+ or -) 90°.

- Scribe all lines in the other direction

Break

Breaking in the first direction

- Find the top edge of your sample.

- Align the hairline with a scribed line

- Move up by 63.5mm (click the dash & arrow-up button)

- Press

Record Drop Position - Move back down by 63.5mm (click the dash & arrow-down button)

- Press

Drop- To check that the break is successful, open the hood window, press with your finger the membrane and see from the microscope camera that the two pieces are indeed split.

- Move to the next scribe line, align, and press

Drop - Repeat the previous step until everything in the current direction is broken.

- You don't need to

Record Drop Positionevery time. The first time is sufficient.

- You don't need to

Breaking in the other direction

- Rotate 90°

- Bring the bar above the entire wafer.

- Align the hairline with a scribed line

- Press

Record Drop Position - Press

Drop - Move to the next scribe line, align, and press

Drop - Repeat the previous step until everything in the current direction is broken.

Your wafer is died successfully!

- Press

Unload Wafer

Remove chips, unload and cleanup

- You can remove your chips from the membrane inside the hood.

- Bring your sample box inside the hood, detach each die and store it in your box.

- Do you have any excess pieces that you will not use?

- Store them in your box and discard them in the cleanroom at the designated III/V wafers waste

- You can read more about the waste handling inside and outside the cleanroom in the page Waste handling

- Do you have any excess pieces that you will not use?

- Separate the tape ring inside the hood

- Detach the membrane

- Fold the sticky side

- Dispose it at the III/V waste bin below the table

- Wipe down the surfaces with ethanol

- Dispose your gloves and wipes at the III/V waste bin below the table

- Bring your sample box inside the hood, detach each die and store it in your box.